The production of asphalt for road surfacing generates a fine dust which cannot always be included in the finished product and has to be sent to landfill.

Materials efficiency and recycling

We continue to make progress against all our key metrics. The amount of crushed road waste or recycled asphalt planings (RAP) used in new asphalt mixes rose again. The average RAP content increased to 14 per cent in 2017 and continues to rise, led by our subsidiary MQP which has one of the best RAP useage rates in the industry at 23 per cent.

Mixing RAP into asphalt makes sense for customers, the environment and the business. It means less virgin aggregate and bitumen are needed, and waste to landfill is reduced, though there is a trade-off between the use of more recycled asphalt and energy consumption. The UK specification allows up to 50 per cent RAP in various asphalt products and we continue to develop new techniques to increase the content in our mixes.

The cement replacement Regen is manufactured from granulated blast furnace slag, a by-product of the steel industry. It reduces embodied CO2 in concrete and provides a number of other benefits. Its use in ready-mixed concrete means we have one of the highest cement replacement rates in the UK market. We are working towards our target of 45 per cent cement replacement by 2020 and are developing mixes with higher Regen content. We are also communicating the CO2 benefits of these products to customers and specifiers through a national programme of CPD courses on the ‘Benefits of cement substitutes’.

-

Recycled and secondary materials

2010 (baseline)

2015

2016

2017

Definition

By-products or waste used as raw material in cement

8.0%

11.6%

12.2%

11.5%

Alternative materials as a % of total cement production

Aggregates recycled and sold

1.77%

1.50%

0.19%

0.01%

% of total sales

Recycled materials in asphalt (Hanson plants)

2.9%

8.6%

11.1%

10.5%

% of recycled asphalt planings and foundry sand used in asphalt

Recycled materials in asphalt (MQP plants)

26.6%

19.3%

22.9%

% of recycled asphalt planings and foundry sand used in asphalt

Recycled materials in concrete

0.08%

0.06%

0.22%

0.11%

% of recycled aggregate used in ready-mixed concrete

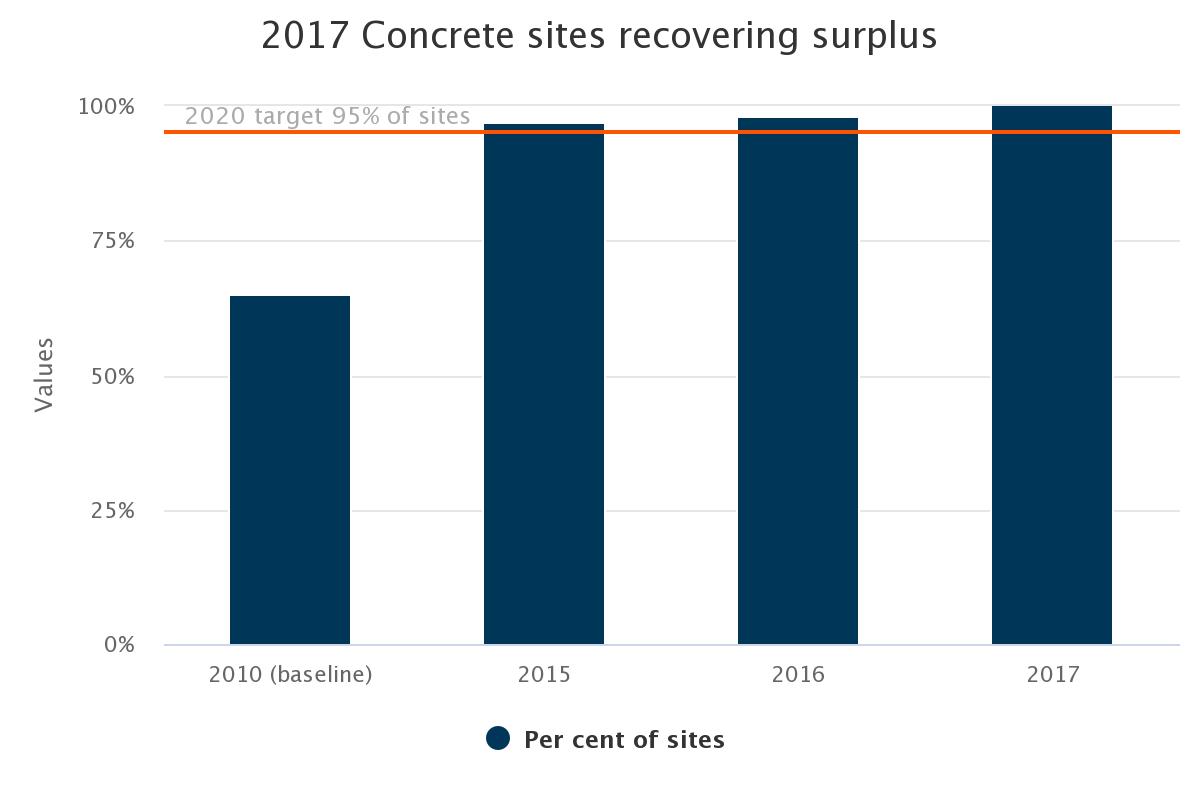

Sites which recover surplus concrete

65%

97%

98%

100%

Sites recovering over 50% of process waste (inc third party recycling)

Cement replacements in concrete (Regen, PFA)

38.4%

37.0%

38.9%

38.3%

% of cement substitutes in ready-mixed concrete