Energy efficiency

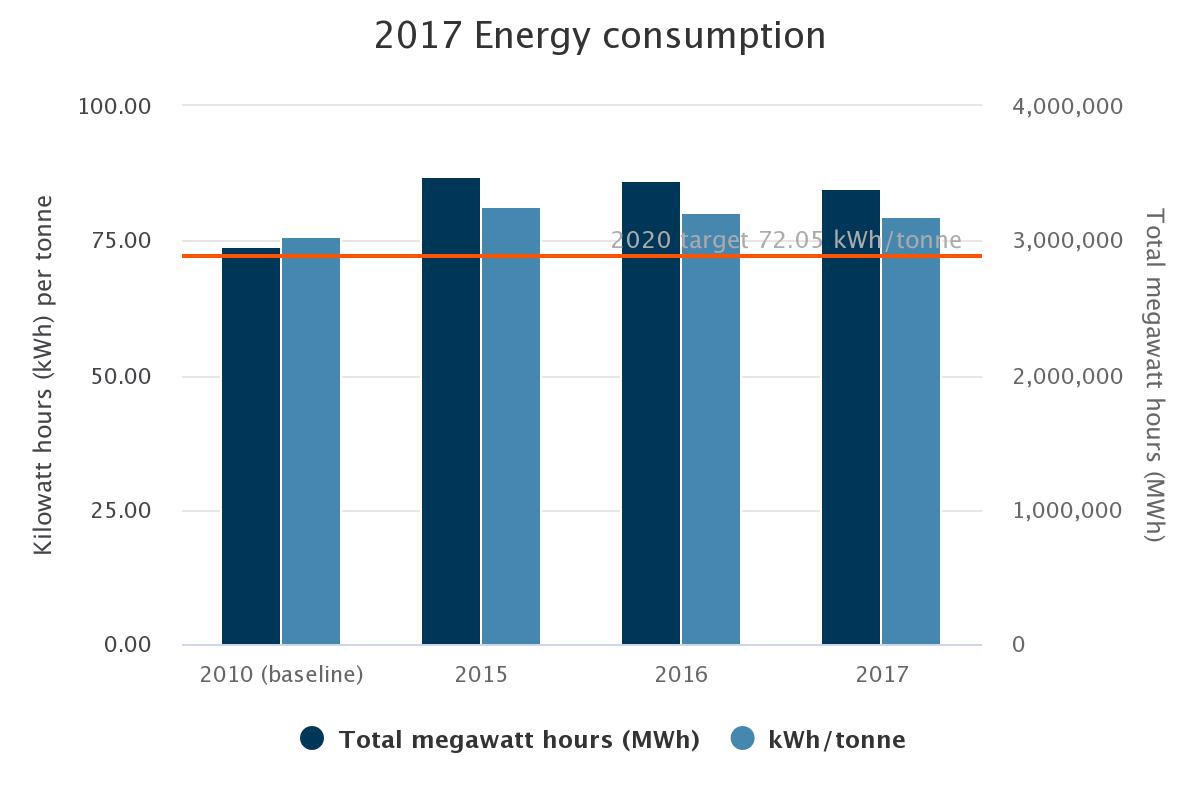

Total energy consumption per tonne fell for the third consecutive year, and there was a 0.8 per cent fall in energy use per tonne of product from 2016. The reduction was due to a range of factors including an increased focus on energy efficiency and energy-saving initiatives as our ISO 50001 systems become embedded into the business. The number was also influenced by product mix as the energy intensity of our individual products can vary greatly.

To overcome the changes in product mix, our ISO 50001 systems normalise production levels to a known baseline output. We are still behind the 2010 figure in terms of kilowatt hours per tonne. In this case when the 2017 data is normalised to the same product mix, the number is 0.9 per cent better.

Our focus has been to improve efficiency through our management system and we continue to invest in new technology and embed both best practice and energy awareness into the business. We run continuous improvement programmes and encourage employees to enter good ideas into our opportunities database or share them through the sustainability matters working groups.

-

Energy consumption

2010 (baseline)

2015

2016

2017

% change since 2010

% change since 2016

Energy consumption – kilowatt hours per tonne

75.84

81.29

80.38

79.73

5.3%

-0.8%

Energy consumption – total megawatt hours

2,964,572

3,485,372

3,456,773

3,388,789

14.3%

-2.0%

When normalised for production changes at business line level, the 2017 performance is 72.4 Kwh/tonne against a 2010 baseline of 73.0 Kwh/tonne, showing a reduction of 0.86%..